Model No.︰DY-00424-23

Brand Name︰Denxy/OEM

Country of Origin︰China

Unit Price︰US $ 56 / BOX

Minimum Order︰1 BOX

Denxy Dental Zirconia Blocks

Pre Colored : A2, A3

zirconia blocksare made of nanometer medical grade zirconia powder. The powder are firstly compacted by cold isostaticpressing with high compressive strength and then pre-sintered to a certain degree to offer good machinability.

Us zirconia blocks can be used to create crowns, bridges, inlays and veneers of fixed partial denture with different translucency levels and colors.

1. Product Information

Compositions: ZrO2(94%-95%), Y2O3(4.5%-5.5%), AL2O3(0.2%-0.5%), other Oxides (<0.5%)

Grade: High Translucency, Super High Translucency

Compatibility: open dental milling system

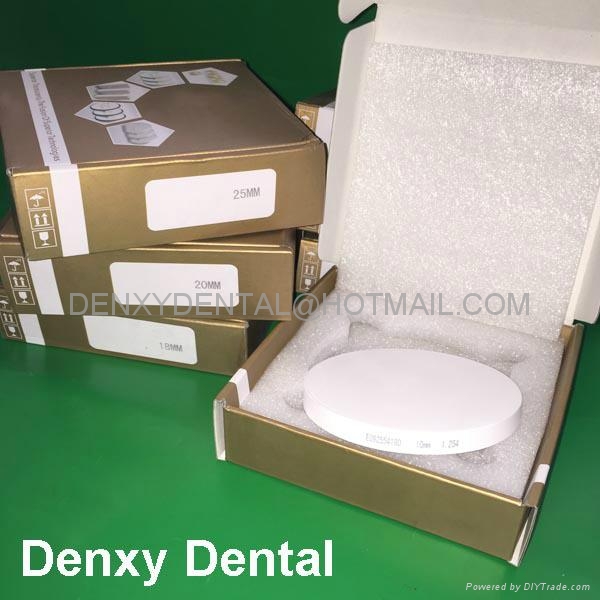

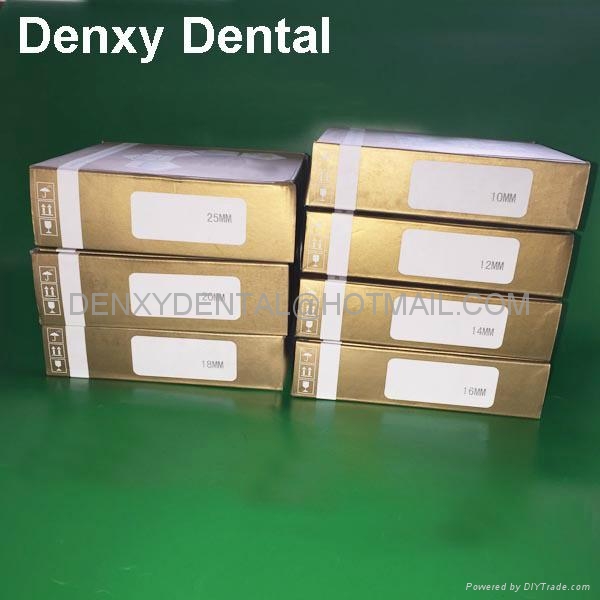

Specifications: ø98 x 10, ø98 x 12, ø98 x 14, ø98 x 16, ø98 x 18, ø98 x 20, ø98 x 22, ø98 x 25, ø98 x 28

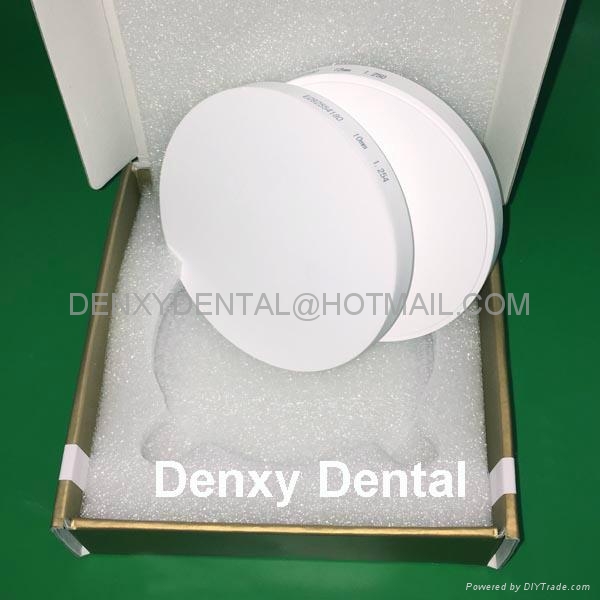

Appearance: white color disc

2. Technical Facts

Pre-sintering Density: ≥ 2.95g/cm3

Post-sintering Density: ≥ 6.08g/cm3

Post-sintering Hardness: Hv10 ≥ 12.5Gpa

Post-sintering Flexural Strength: > 1100Mpa

SinteringShrinkage: 19% - 22%

Pre-sintering Solubility: ≤ 2000µg·cm-2

Post-sintering Solubility: ≤ 100µg·cm-2

Radioactivityof uranium-238 per unit mass: ≤ 0.02Bq·g-1

3. Operation Guide

Price Terms︰ Shanghai, Guangzhou, Shenzhen, Hongkong

Payment Terms︰ Western union / TT